How to Choose the Right Material for Plastic Injection Moulding?

Warning: Undefined variable $post in /home/dietofli/public_html/wp-content/plugins/code-snippets/php/snippet-ops.php(582) : eval()'d code on line 3

Warning: Attempt to read property "ID" on null in /home/dietofli/public_html/wp-content/plugins/code-snippets/php/snippet-ops.php(582) : eval()'d code on line 3

The estimated reading time is 3 minutes

Warning: Undefined variable $post in /home/dietofli/public_html/wp-content/plugins/oxygen/component-framework/components/classes/code-block.class.php(115) : eval()'d code on line 3

Warning: Attempt to read property "ID" on null in /home/dietofli/public_html/wp-content/plugins/oxygen/component-framework/components/classes/code-block.class.php(115) : eval()'d code on line 3

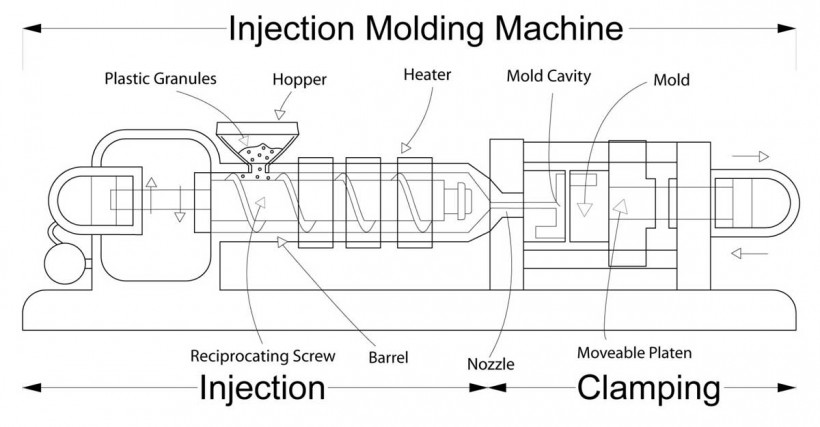

The plastic injection molding technique is a way of making the desirable 3d product by pouring the melted hot plastic material into the molds of the specific desired shapes. Forme Technologies bespoke plastic moldings is a company that is experienced in making the products out of ideas into a real form. The material is the main item that plays a vital role in the success of the outcome.

The selection of the right raw material ensures a desirable product. There are thousands of materials that have made the selection difficult. The material type also depends on the desired product characteristics like for which [ purpose the product is going to be used.

Following are the parameters that are needed to consider while selecting the raw material:

The weight of material:

The weight of the raw material is very important to consider in selecting the raw material. If you need finished product-like toys to be lightweight, then the raw material weight should be as less as possible because no one likes heavy toys that are difficult to carry and hold. The lighter the raw material, the lighter will be the finished product.

The density and the weight of the raw material predict the weight of the final product. If the client demands heavyweight products, then the raw material will be chosen that has more weight along with all the other features. You cannot skip other features because of one preferred point.

The cost of materials:

The cost of the raw material is an essential matter that determines the cost of the whole batch. Plastic injection molding is mostly done for large-scale product production like for the selling business. Money and budget are some of the main parameters that are important for a business person. For a business, you need to raise the profit by spending less money.

So the raw material should be chosen that costs cheaper but still provides satisfactory other features to not compromise the quality of the product.

Material flexibility:

Material flexibility is the parameter that is needed to consider according to the client's preference for the product. The softer the material, the higher will be the flexibility. The hard materials show the least or no flexibility. Flexibility is the inner character of the material to bend easily without breaking when applying pressure or stress.

While placing an order, you should ask about the detailed demands of the client just to make sure about the characteristics of the final product. If the product needs to be flexible, then the soft raw material will be preferred.

The hardness of the material:

It is the physical parameter of the raw material that has been asked before starting the whole process of manufacturing. There is a scale that is specific in defining the hardness level of the raw material. The scale reading is from 0 to 100.